The GSPS Advantage

Customer Focused

GSPS Pump designed the best Instant-Prime® Pumps with our soul and heart. Before we design, an extensive discussion is held within our team and everybody envisions what our “baby” will look like, what unique and outstanding functions we should pursue, what material we should select to make sure it has a strong “body”. All ideas and proposals are then filtered, optimized, and improved to make sure our “baby” will win huge advantages after it is born. Just like the IT industry, we have also actively invited our customers from all over the world to participate in this iterative design process. After numerous hours of back and forth, Instant-Prime® Pumps are finally born into the world through the joint efforts of our great customers and the GSPS Pump team. We are now ready to challenge the world.

Innovation Driven

From the moment GSPS Pump was born, we started thinking about how to be different and how to create more value for our customers. Innovation is the beating heart of our team. We thrive to think outside the box to bring to market a unique product that will bring great advantages and benefits. We challenged traditional quality control methods and innovatively created a production-inspection integrated process in our centrifugal pumps' production. Innovation is the driving force during GSPS Instant-Prime® Pump's design and development.

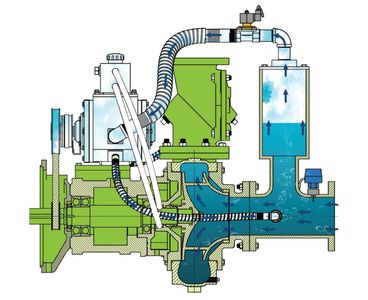

Quality Amplified

We believe product quality is the key to success. We focus on every component to make sure there is no weak link in our system. A wide variety of tests were conducted in the past two years, with certain tests repeated over ten thousand times. Our goal is to identify all potential problems before we introduce these pumps onto the market.

Durability and reliability can’t define product quality alone. That’s why we are adding “capability” to the meaning of quality by improving our product performance index in all aspects and making the impossible, possible.

By partnering with the most advanced diesel engine leaders like Cat, Cummins, Deutz, Hatz, etc., and some well-known control panel manufacturers in the world, we make sure we are using the best components to build all of our equipment. At GSPS Pump, we believe you get out what you put in.

Fabrication Elevated

GSPS Pump has a state-of-the-art fabrication center in China, where we rely on our intelligent fabrication team, which consists of laser cutters, CNC benders, welding robots, high precision assembling tables, and the smartest fabricators.

Every Instant-Prime® Pump is 100% made in house, including centrifugal pump, vacuum pump, skid, trailer, and canopy. We have large production facilities both in China and Houston. Our standard configured products are fabricated in China; while custom and urgent orders will be assembled at our Houston facility.

Fabrication seems easy, but high-quality fabricated pump packages are never as easy as you might think. We invested heavily in importing from Europe the high precision assembling tables, which play a very important role in our cutting and assembling process for manufacturing pump skids, fuel tanks, and canopies.

Copyright © 2025 GSPS Pump - All Rights Reserved